Dies

In tandem with punches, cutting dies ensure precise cutting, folding, or forming of your pieces. Our standard cutting dies are available as blanks in stock and machined according to your needs. We also create custom dies based on your drawings to meet all your requirements.

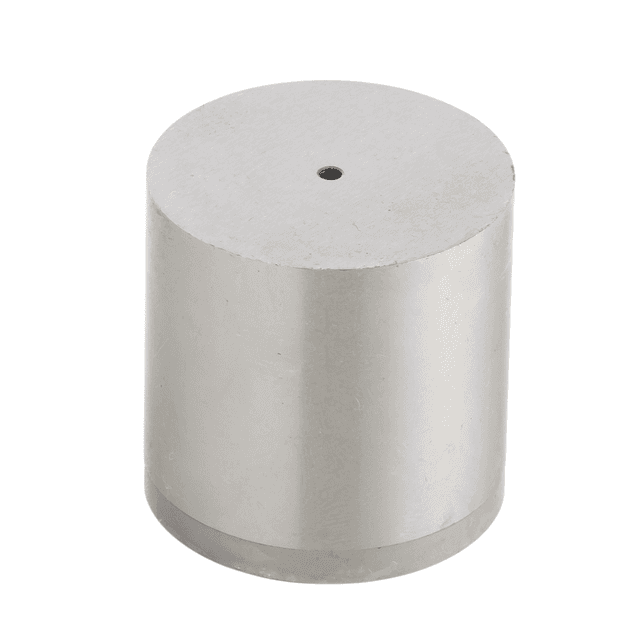

Headless die button with taper relief D_-SM__ / D_-SH__

Headless die button with counterbore relief D-SMC_ / D_-SHC_

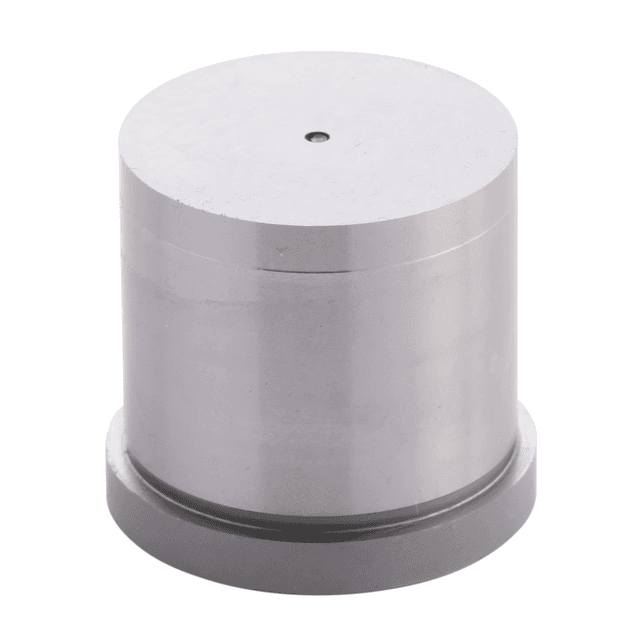

Headed die button with taper relief D_-HM__ / D_-HH__

Headed die button with counterbore relief D_-HMC_ / D_-HHC_

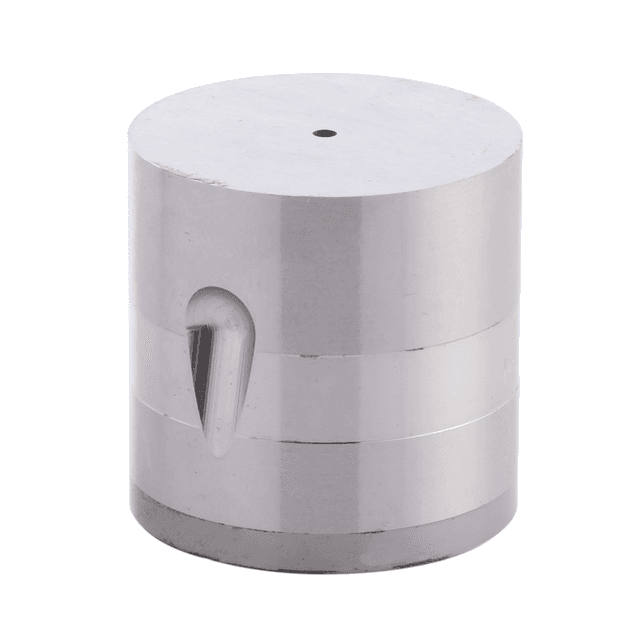

Key located headless die button with taper relief D_-SCWB / D_-SCD_

Key located headless die button with counterbore relief D_-SCCB / D_-SCC_

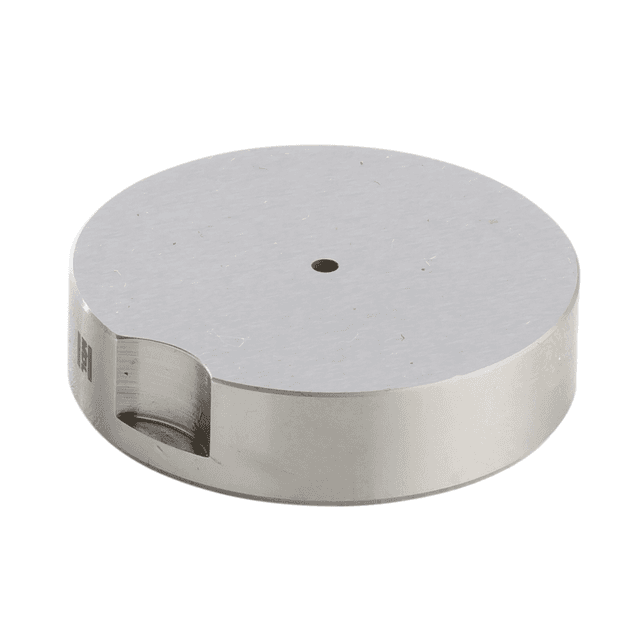

Low profile reversible die button DA-SRWB / DA-SRD_

Low profile key located die button D_-SSWB / D_-SSD_

Ball-lock die button DA-BLCB / DA-BLC_

Standard Dies

The standard Porter Besson dies from our catalogue are available in stock in four different types based on requirements:

Straight Die:

Smooth dies are available in two tolerance classes, h5 and m5. The m5 tolerance allows for mallet assembly (force locking) when the die has an alignment plate, while with h5 tolerance dies, the locking must be mechanical. They are available with either a cylindrical or tapered draft. The draft allows for waste evacuation during cutting. Smooth dies are made with a pre-centering diameter.

Headed Die:

Flanged dies are available in stock in two tolerance classes, h5 and m5. The flange allows for axial stoppage of the die. They come with cylindrical or tapered drafts, allowing for waste evacuation during cutting. All our flanged dies have a pre-centering diameter.

Ball-Lock Dies:

Ball-lock dies allow for easy and quick removal of the die through a ball fixation.

Low profile straight Dies:

Low profile straight dies are available in both reversible and non-reversible versions. The reversible version can be flipped when the die is worn to reuse it. They help address space constraints. The draft is then located on the die holder.

Oriented Dies:

Oriented dies allow for mechanical clamping and orientation of the die using an M8 washer with a h6 diameter. The M8 thread enables the washer's extraction.

For any non-standard requirements, we also create custom dies.

Dimensions

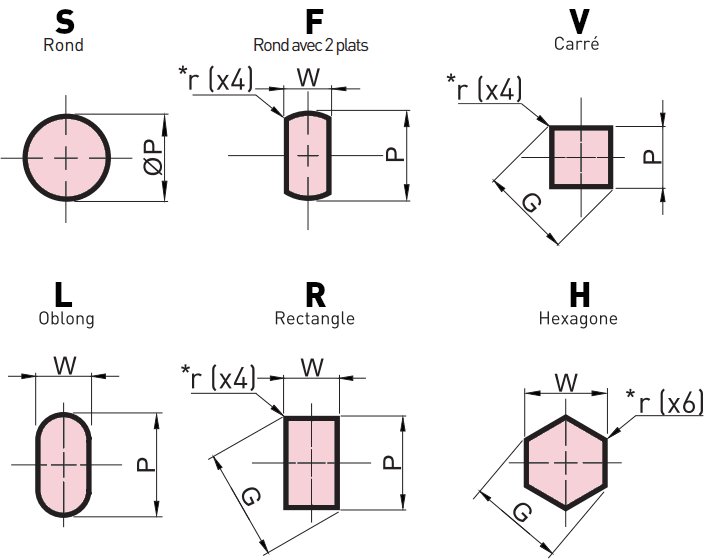

Dies are characterized by the following dimensions:

Body Diameter (D)

Total Length (L)

Height (H)

Form Dimension: P and W for form dimensions.

Form Orientation (form dies are oriented using an alignment plate).

All these dimensions must be specified in your price inquiries.

Les Matières

AMDL propose plusieurs nuances de matière :

Material A Z160CDV12 : 12% Chromium Highly Alloyed Steel

High Hardness: 58 - 62 HRc

Used for thin sheets and modest hardness.

Note: An additional tempering process is required for coating.

Material B High-Speed Steel (HSS) : Z90WDCV

High Hardness: 60 - 64 HRc

Used for hard sheets (Stainless Steel / High strength steel...)

Material C Carbide

The hardest material we can offer. Very brittle. This material is used for high-speed applications and flat cuts only (not compatible with lateral forces).

Material E ASP 23

High Hardness: 62 - 66 HRc

Sintered High-Speed Steel (powder technology). Less fragile, resistant to breakage. Very good compression resistance.

Material K X110 CrMoV8 - T6

High Hardness: 61 - 63 HRc

Combines the hardness of Material B with the resilience of Material A. This material offers an excellent technical compromise.

Material S M4/1.3351/HS 6.5.4

High Hardness: 62 - 66 HRc

If you have a specific material requirement, please let us know, and we will assess its feasibility.

Custom Dies

As a manufacturer and expert, in addition to our standard catalogue of in stock dies, we also create all your custom dies according to your drawings. To do so, simply send us your plan via email, and our sales and technical team will process your request within 48 hours. With over 30 years of expertise, we are well-equipped to meet your needs with efficiency and technical expertise.