Capabilities

Length

4500 mm

Width

2300 mm

Height

1600 mm

Table dimension

4000 mm x 2200 mm

Annealing cycle

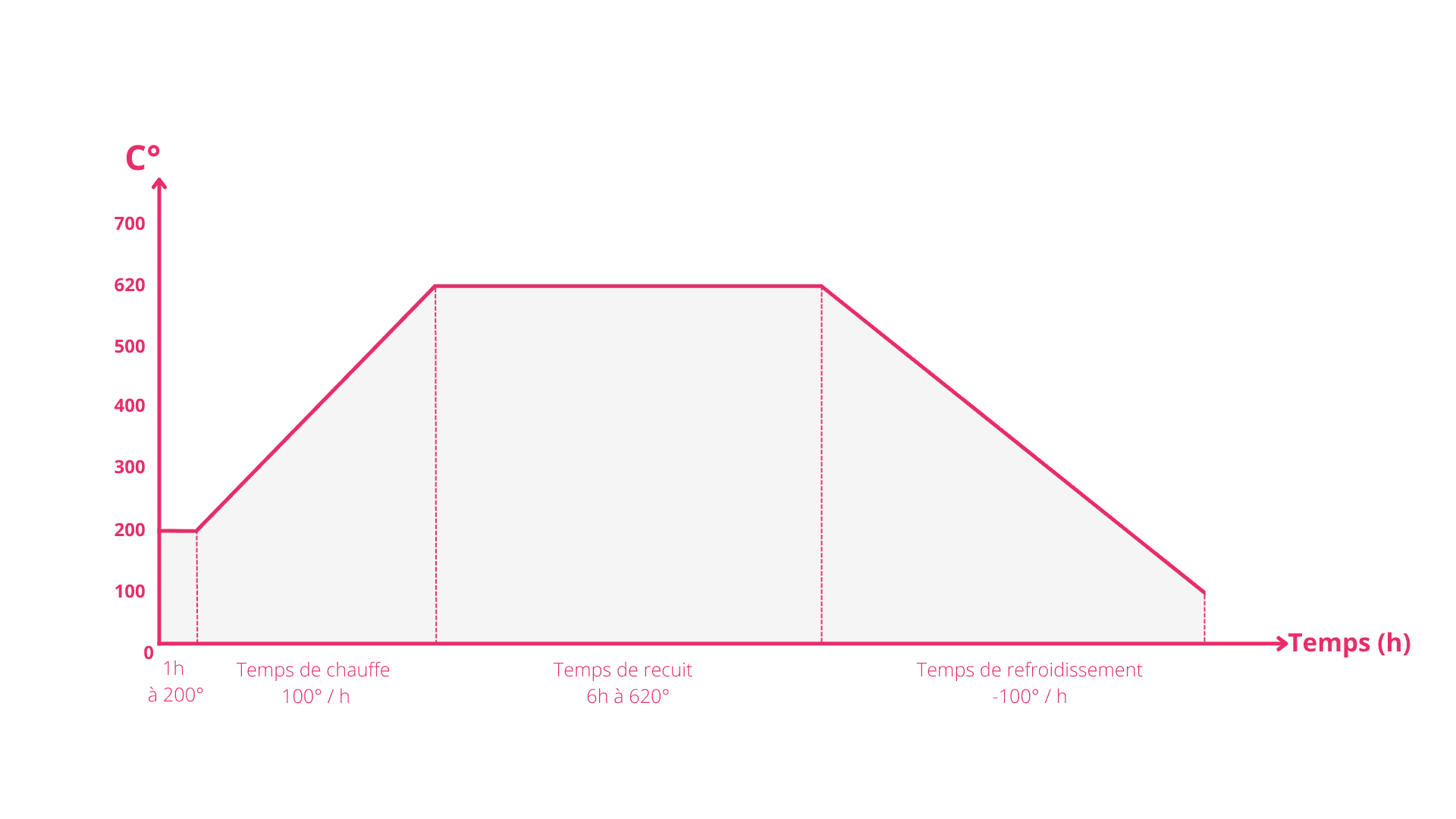

To ensure effective stabilization of parts, we employ a carefully designed and controlled annealing cycle suited to the pieces' dimensions. The cycle always consists of three phases:

- 1st phase: controlled warm-up

- 2nd phase: Maintaining a consistent temperature.

- 3rd phase: slow cooling inside the furnace.

This cycle is adaptable to specific requirements.

Annealing benefits

Stabilization annealing has many advantages and is an essential step in the production of machined parts. Thus the main advantages are:

- Reduction of internal stresses and strains : The manufacturing process and various operations applied to steel (or other materials) generate internal stresses and strains. Annealing reduces and eliminates accumulated tensions. This process enhances dimensional stability and reduces the risk of deformation, increasing the part's reliability and durability. Stabilization annealing reduces strains that have been accumulated during the production process (forging, hot rolling, wielding).

- Homogeneous Internal Microstructure : Stabilizing the part leads to grain recrystallization, creating a uniform and homogeneous microstructure. This improves mechanical properties (increasing ductility, resilience, toughness, and strength) and ensures a consistent response to applied stresses during demanding applications.

- Further manufacturing processes facilitation : By reducing durations and improving machining, stabilization annealing lowers production costs (tools lifespan). You also receive a more precise and accurate part, thanks to reduced risks of deformation during machining.

All plates used in the construction of your custom-machined blocks or plates go through our stress-relieving furnace to guarantee high-quality results.

Our creations

What is Stabilization Annealing?

Stabilization annealing is a heat treatment process used to eliminate stresses and tensions within steel. These come from the steel's production process. It is a crucial step in steel machining, reducing lead times, improving precision, and preventing deformations in future machining.

Frequency of Stabilization Furnaces

We conduct stress relief annealing weekly in our gas furnace. This means our furnace is operated at least once each week.

We have been conducting stress relief annealing for over 30 years! Do you have parts that need stabilizing? Contact us to find out the date of our next furnace run!

Materials benefitting from annealing.

Numerous materials can benefit from the advantages of annealing, including:

- All Types of Steel (Alloyed, Carbon, Stainless, etc.): Annealing eliminates internal stresses, stabilizes the crystalline structure, and enhances the mechanical properties of steels. For alloyed steels, it reinforces their strength and durability, while for carbon steels, it ensures reliable mechanical properties. For stainless steels, it improves corrosion resistance and eliminates stresses from welding or forming.

- Brass: Annealing enhances the mechanical properties of brass by reducing internal stresses, its' ductility, and makes it easier to form and machine. Annealed parts made of brass better withstand mechanical stresses and retain their shape and strength under demanding conditions.

- Aluminium: Annealing improves the dimensional stability and mechanical properties of aluminium alloys. By reducing residual stresses, it prevents deformations and cracks. It also promotes the formation of a homogeneous microstructure, strengthening the aluminium's resilience, ductility, and toughness, preparing it for demanding applications.

- Titanium: Annealing enhances the mechanical properties of titanium alloys by eliminating internal stresses and stabilizing the crystalline structure. This leads to improved tensile strength, resilience, and corrosion resistance, crucial characteristics for aerospace, medical, and industrial applications.

Annealing applications

Annealing finds use in numerous industries and sectors. For example:

- Automotive industry: annealing is widely used in the automotive industry to relieve stresses in parts such as drive shafts, chassis components, and forged pieces. This reduces the risk of deformation and cracks.

- Aerospace: In aerospace, aircraft parts or components of engines regularly undergo heat treatments and shaping. Annealing ensures dimensional stability, reliability, and durability.

- Oil and gas industry: Equipment used in oil and gas exploration and production, such as tubes and pipes, undergo plastic deformation and heat treatments. Annealing is used to reduce stresses and improve the strength and resilience of the parts.

- Electronics industry: In the production of electronic components, annealing is used for connectors, printed circuits, and semiconductors to eliminate stresses resulting from manufacturing processes and to enhance the quality and reliability of the final products.

- Medical Industry: Medical devices, such as implants and surgical instruments, often require heat treatments to adjust their mechanical properties. Annealing is used to eliminate internal stresses and ensure better biocompatibility.

- Construction: In the construction industry, annealing is used to fortify structural steel elements like beams, columns, and cables. This mitigates the risks of deformation and cracking due to applied loads.

- General Manufacturing: In various other industrial applications, annealing is used for various metal parts and components, ensuring their quality, strength, and stability under specific usage conditions.

We conduct annealing for all your parts based on specially defined cycles to meet your specific requirements. Contact us!